Modernization – Optimization

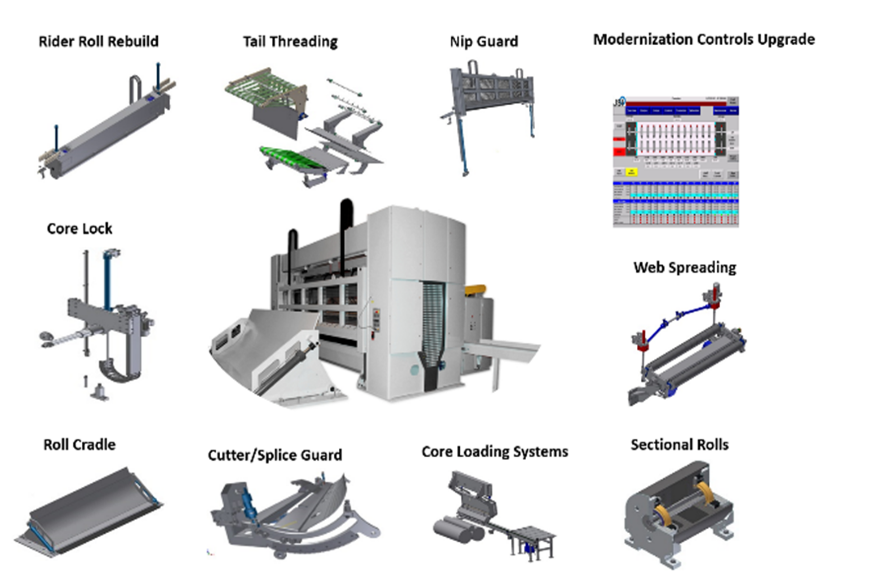

JSI solutions for winder upgrades will increase equipment service life and improve performance. A variety of ready-made and custom solutions can be utilized to maximize the performance of existing equipment.

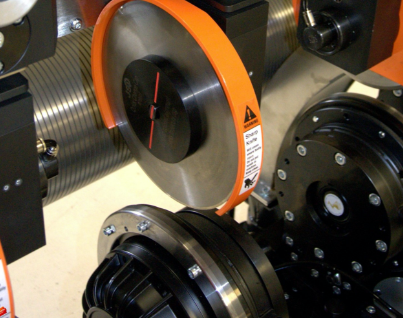

Winder Rebuilds

To counter the ever-increasing cost of new machinery, JSI offers a winder-rebuilding service that upgrades existing winders to like-new condition for a fraction of the cost of a new winder.

- New controls and a new HMI system

- Control system updates

- Automatic slitter positioning technology

- A dual spreader

- A direct-acting rider roll

- Auto core feeding and end gluing for capacity improvement

- Runnability improvements by new sectional rolls

- A safety system upgrade

Performance Optimization

JSI provides engineered controls systems and software solutions for the paper industry. Automation services from JSI offer performance optimization, products and troubleshooting projects to ensure safety and maximum efficiency of equipment and processes.

Winder cycle time reductions are a cost-effective way to increase throughput, utilizing existing winder equipment to its full potential. Existing automated sequences can be fine-tuned with a methodical approach that combines the PLC controls, hydraulic and pneumatic controls, and the process conditions. Cycle time reductions of even seconds in individual movements and actions within a sequence can yield a significant improvement in winder throughput in a 24-hour period.

Winder Modernization

Capacity can make all the difference in a mill operation. For those who do not want to purchase new machines with larger capacities, JSI offers improvements to existing winders in lieu of such a large commitment. JSI supplies proven upgrades — an option not selected during the initial purchase or a customized solution — to existing winder setups. Upgrades can be made to tail threading, core loading sequences, automatic set change functions, and more. Our winder-specific engineered solutions provide a reliable and cost-effective approach to winders of all manufactures and capacities.

Case Study

- Scope: Reduce setup time and increase accuracy.

- JSI Solution: Replace current drive system with new Rockwell Servo system and change out current encoders with new absolute magnetic encoders.

- Results: JSI reduced setup time from over 4 minutes to under 1 minute

Troubleshooting

Troubleshooting old and new winder controls and several generations of control technology can be challenging. At times, existing functions and automation are no longer used due to reliability issues, faulty equipment, or faulty sensor technology. Identifying the root cause of these problems and addressing them can return the lost functionality back to operation and increase the overall productivity of the winder.

Program Changes

Process and equipment changes may require program changes for the winder to operate efficiently and safely. Program simulation prior to actual changes provides a solid understanding of the effects of the changes and may be used to reduce the commissioning time of new functions, thus reducing the machine downtime.