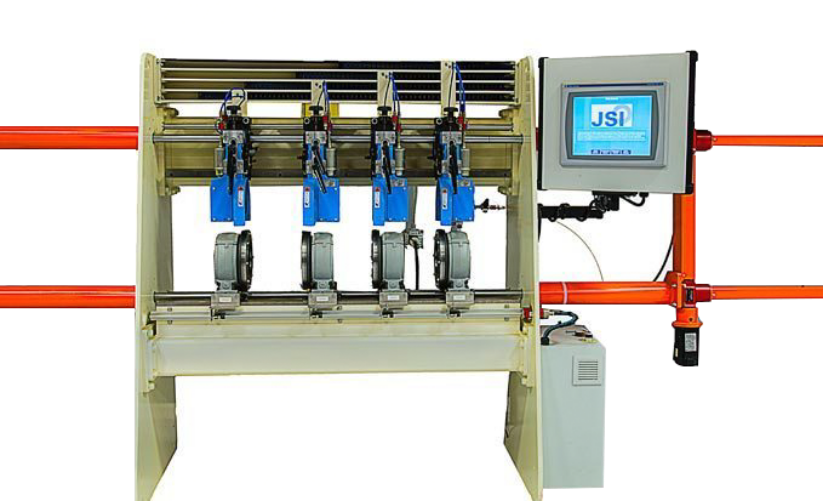

Accu-Slit R (Rod)

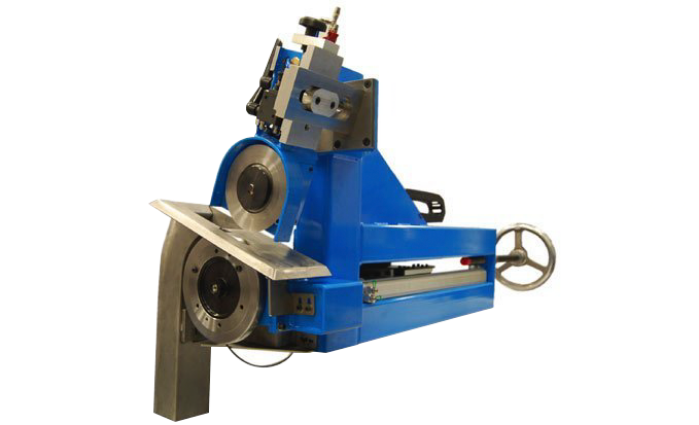

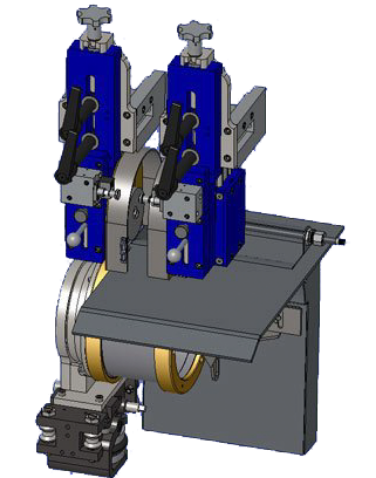

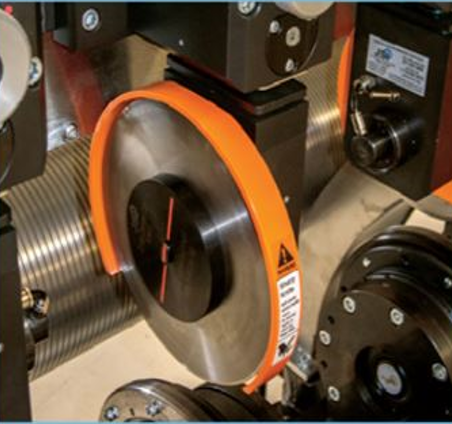

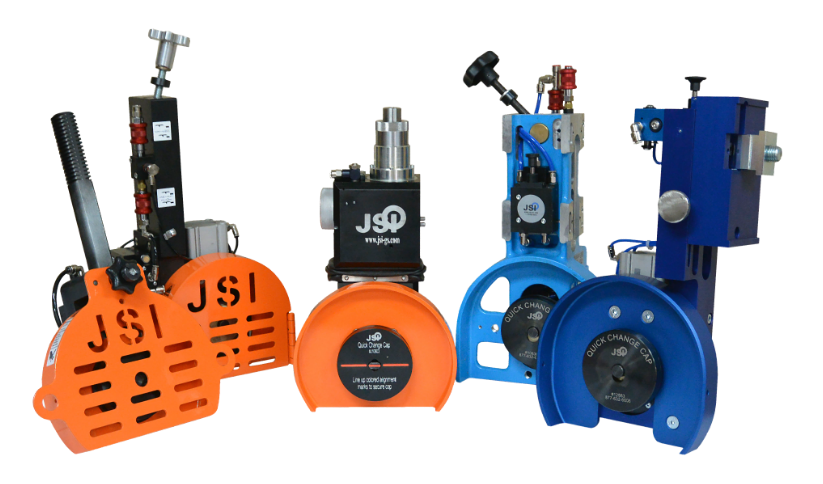

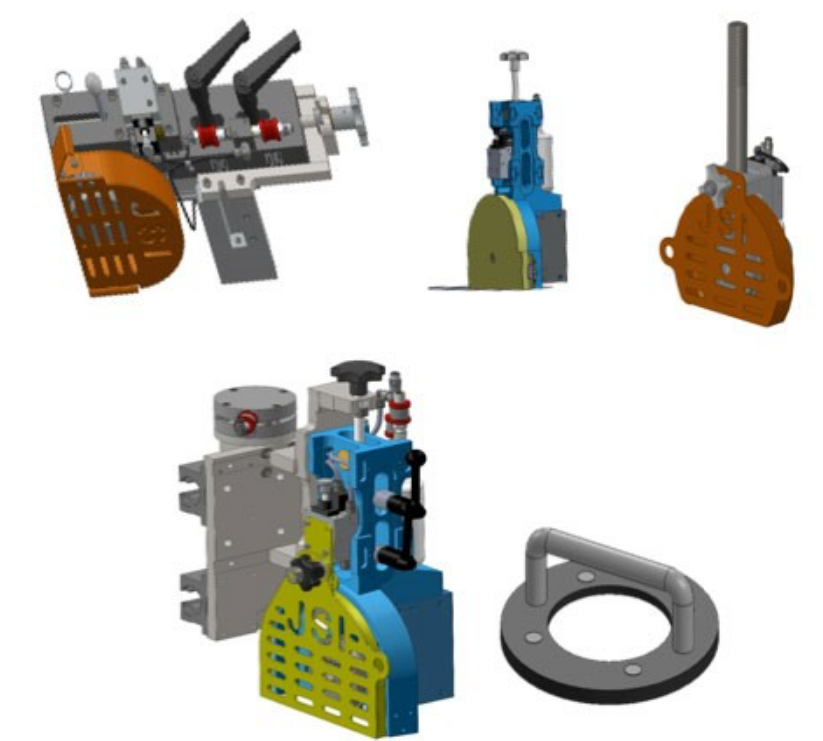

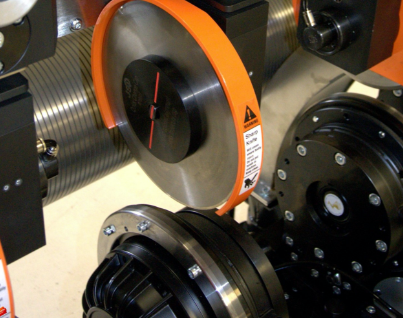

Transfer rod positioning systems are the solution when simple and effective automatic slitter positioning is needed. This traditional slitter positioning system utilizes a single servo motor with linear transfer rods for top and bottom slitter carriages. These carriages then clamp onto the rods for movement and transfer to the fixed rails during slitter operation. An absolute encoder continually monitors the position of each slitter carriage.

- Fast: Rod-style servo motion, moving up to 4 positions at one time. Most set-ups achieved in under 1 minute.

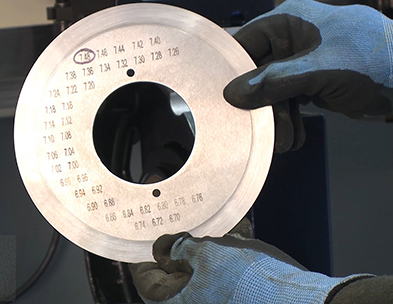

- Accurate: Absolute magnetic encoders at each position +/-.015” accuracy.

- Controls System: Industry leading Rockwell Automation control system.

- Technology: Uses JSI Accu-set Holder for easy, SET IT and FORGET IT, blade set-up.

- Easy: Upgrade to existing systems.

- Cost Effective: Lowest cost option to upgrade to Auto-positioning.